Advanced Wastewater Treatment

SBR Sewage Treatment Plants

Sequencing Batch Reactor (SBR) is an advanced wastewater treatment process that operates

in cycles within a single tank. It combines biological treatment, settling, and decanting in one

system, eliminating the need for multiple tanks.

What is SBR Technology?

Our Sequencing Batch Reactor (SBR) technology incorporates Enhanced Biological

Nutrient Removal (EBNR) to deliver a cost-effective, high-performance wastewater

treatment system. With superior nutrient removal efficiency and improved sludge

settleability, SBR outperforms conventional treatment methods while minimizing both

capital and operational costs.

Key Features of SBR Technology

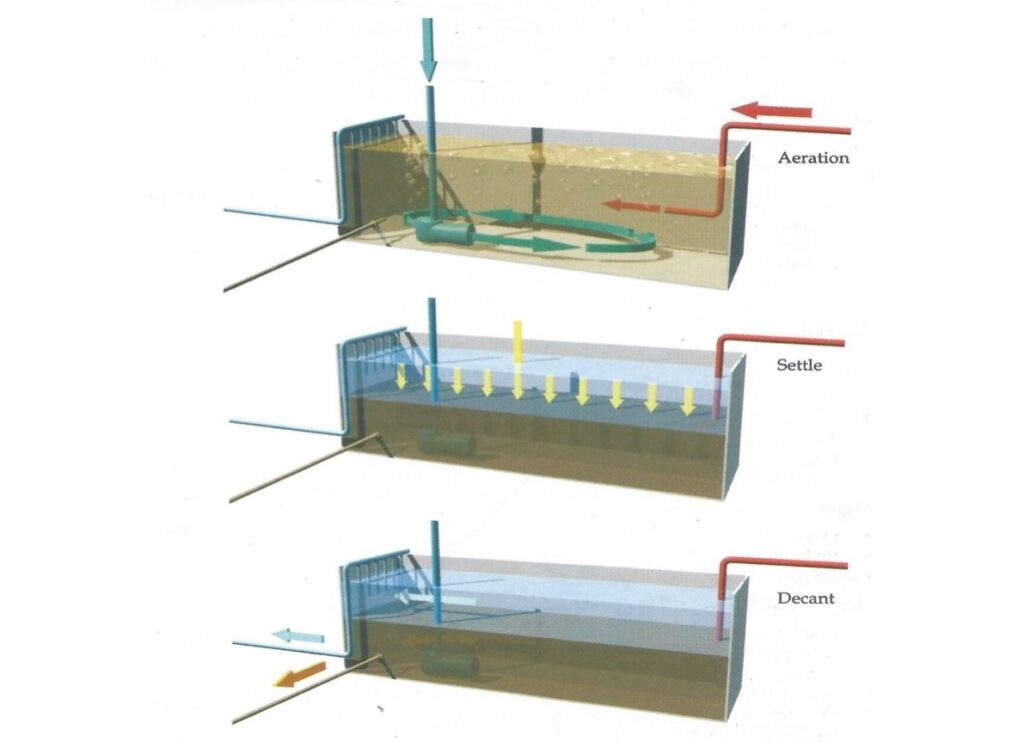

Stages of SBR Treatment

Fill

Wastewater enters the reactor tank, beginning the treatment cycle.

Aeration

Aeration promotes biological treatment, reducing organic matter and facilitating nutrient removal.

Settle

Solids separate by gravity, creating clear treated water above the settled sludge.

Decant

Treated water is carefully removed from the tank, leaving settled sludge for the next cycle.

Key Features & Advantages

Chemical-Free Operation

Achieves complete nutrient removal without chemical dosing, reducing operational costs and environmental impact.

Cost-Effective

Lower capital and operational costs compared to conventional systems due to simplified design and reduced infrastructure requirements.

Easy Retrofitting

Adaptable to existing treatment plants, allowing upgrades without complete system replacement.

Flexible Design

Customizable tank configurations with modular construction allows scalability and adaptability to site specific conditions.

Simplified Process

No secondary clarifier, sedimentation tank, or sludge digestion required. Single-tank system eliminates recycle streams.

Automated

Minimal operator input required with PLC automation.

Stable & Reliable

Resistant to sludge bulking with robust engineering ensuring consistent high-quality effluent output.

Versatile Installation

Suitable for both underground and above-ground setups, adapting to space constraints and site requirements.

Compact Footprint

Requires significantly less land space compared to conventional systems, ideal for space constrained urban locations.

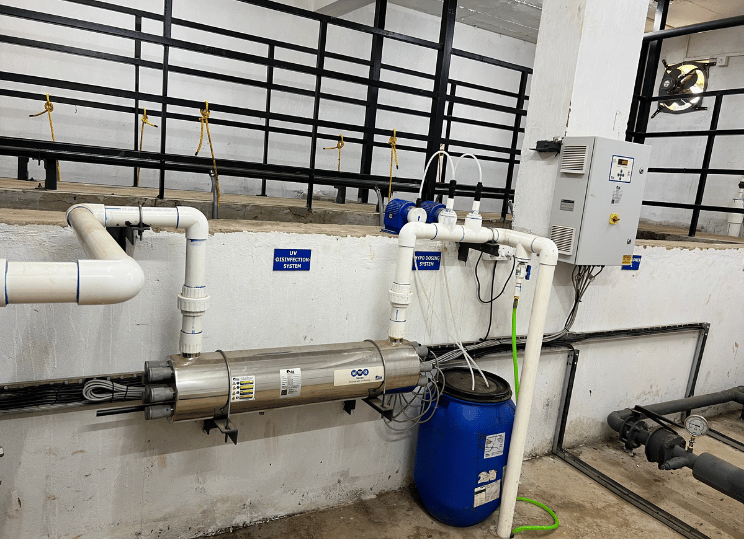

Tertiary Filtration Systems

These are tertiary filtration systems added after decanting, to ensure higher quality of

treated water

Applications & Use Cases

Our SBR technology serves diverse sectors with customized solutions

Commercial Facilities

Suitable for IT parks, shopping malls, office complexes, and commercial centers requiring on-site treatment solutions.

Residential Complexes

Decentralized packaged STPs perfect for apartment buildings, gated communities, and housing developments.

Hospitality Sector

Custom solutions for hotels, resorts, and tourist facilities with variable load patterns and water reuse requirements.

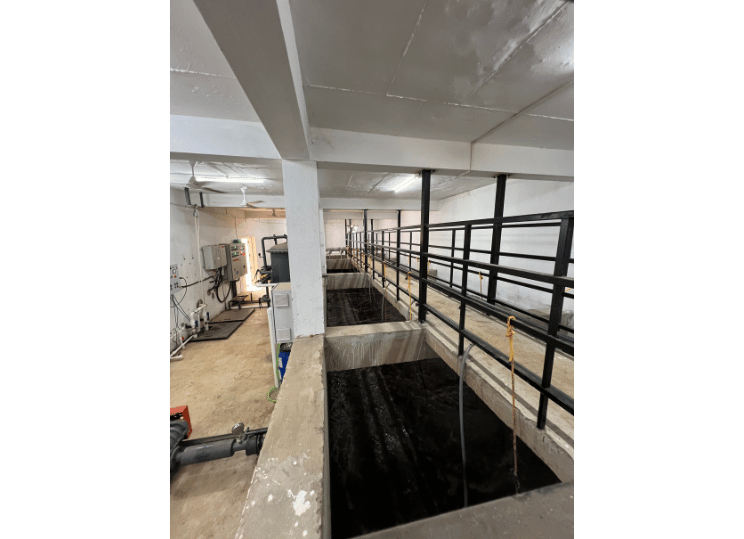

Gallery

Book a Consultation

Let our experts design a customized SBR sewage treatment solution for your

specific requirements